Understanding the Role of Automation in Electroplating Systems

The Evolution of Electroplating Systems

Electroplating, a process that has been around for centuries, involves coating a conductive surface with a thin layer of metal. Traditionally, this process required skilled labor and meticulous attention to detail. However, with the advent of automation, electroplating systems have undergone a significant transformation, enhancing efficiency and precision.

The integration of automation in electroplating systems has revolutionized the way industries approach metal finishing. Automated systems can now handle complex tasks with minimal human intervention, leading to consistent quality and reduced error rates. This shift not only improves productivity but also reduces costs associated with manual labor.

Benefits of Automation in Electroplating

One of the primary advantages of automation in electroplating is the ability to maintain uniformity across large volumes of products. Automated systems are designed to replicate the same process repeatedly, ensuring each item receives the exact specifications required. This level of consistency is difficult to achieve with manual operations.

Furthermore, automation enhances safety in the workplace. Electroplating involves handling hazardous chemicals and working with electrical systems, both of which pose risks to human operators. Automated systems minimize human exposure to these dangers, creating a safer work environment.

Components of an Automated Electroplating System

An automated electroplating system comprises several key components that work together seamlessly. These include:

- Robotic Arms: Responsible for handling parts and ensuring they are precisely positioned for plating.

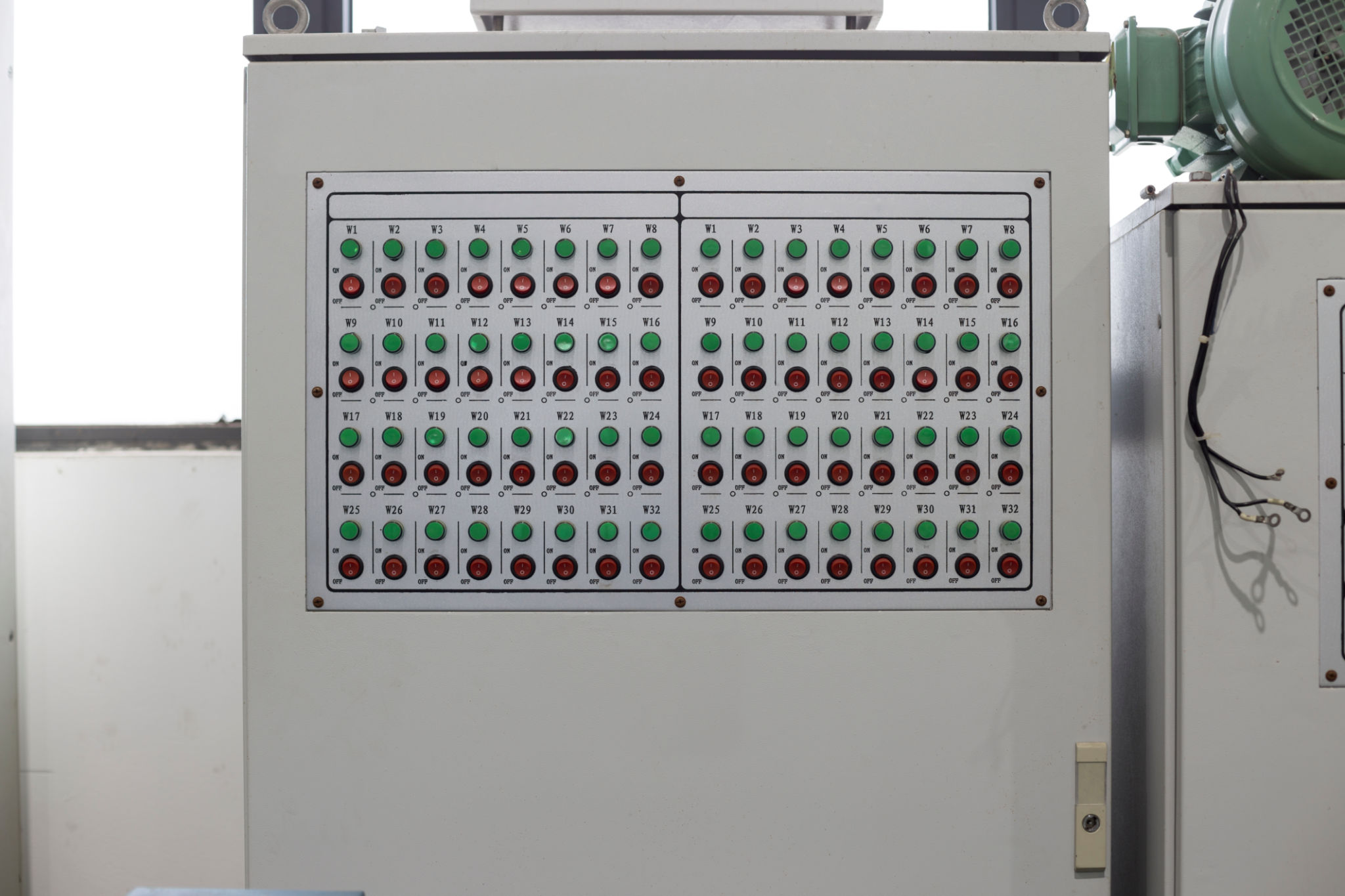

- Control Systems: These systems manage the electroplating parameters, such as temperature, voltage, and time.

- Conveyor Belts: Used for transporting parts through different stages of the electroplating process.

Each component plays a crucial role in the overall efficiency and effectiveness of the system. Together, they enable manufacturers to achieve high-quality finishes with minimal waste.

The Future of Electroplating Automation

As technology continues to advance, the future of automation in electroplating looks promising. Innovations such as artificial intelligence and machine learning are beginning to find their place in these systems, offering even greater precision and adaptability.

For instance, AI can be used to monitor the electroplating process in real-time, making adjustments as needed to optimize quality and efficiency. This level of intelligence ensures that any deviations from the desired outcome are quickly identified and corrected.

Conclusion

In conclusion, automation has become an integral part of modern electroplating systems, offering numerous benefits in terms of quality, safety, and cost-effectiveness. As industries continue to embrace technological advancements, the role of automation is set to expand further, ushering in a new era of innovation in metal finishing.