Understanding Electroplating Systems: A Comprehensive Guide for Turkish Industries

Introduction to Electroplating Systems

Electroplating is a process that involves coating a metal object with a thin layer of another metal through electrochemical deposition. This technique is widely used in various industries around the world, including those in Turkey, due to its numerous benefits such as enhancing corrosion resistance, improving wear resistance, and adding aesthetic appeal.

Understanding the intricacies of electroplating systems can significantly benefit Turkish industries by optimizing production processes and ensuring high-quality outputs. This guide aims to provide a comprehensive overview of electroplating systems, their components, and their applications, specifically tailored for industries in Turkey.

The Basics of Electroplating

The electroplating process mainly involves three components: the anode, cathode, and electrolyte solution. The object to be plated acts as the cathode, while the metal that will coat the object serves as the anode. An electric current is passed through the electrolyte solution, causing metal ions from the anode to deposit onto the cathode.

This process can be used for a variety of metals like gold, silver, nickel, and chromium. The choice of metal depends on the desired properties of the finished product. For example, chromium might be selected for its high corrosion resistance, while gold could be chosen for electrical conductivity and aesthetic reasons.

Components of an Electroplating System

Electroplating systems consist of several key components that work together to achieve a successful coating process. These include:

- Power Supply: Provides the necessary electrical energy for ion transfer.

- Anodes and Cathodes: Materials used for coating and the object to be coated.

- Electrolyte Solution: A liquid medium that facilitates ion transfer.

- Plating Tank: The container that holds the electrolyte solution and suspended materials.

Applications in Turkish Industries

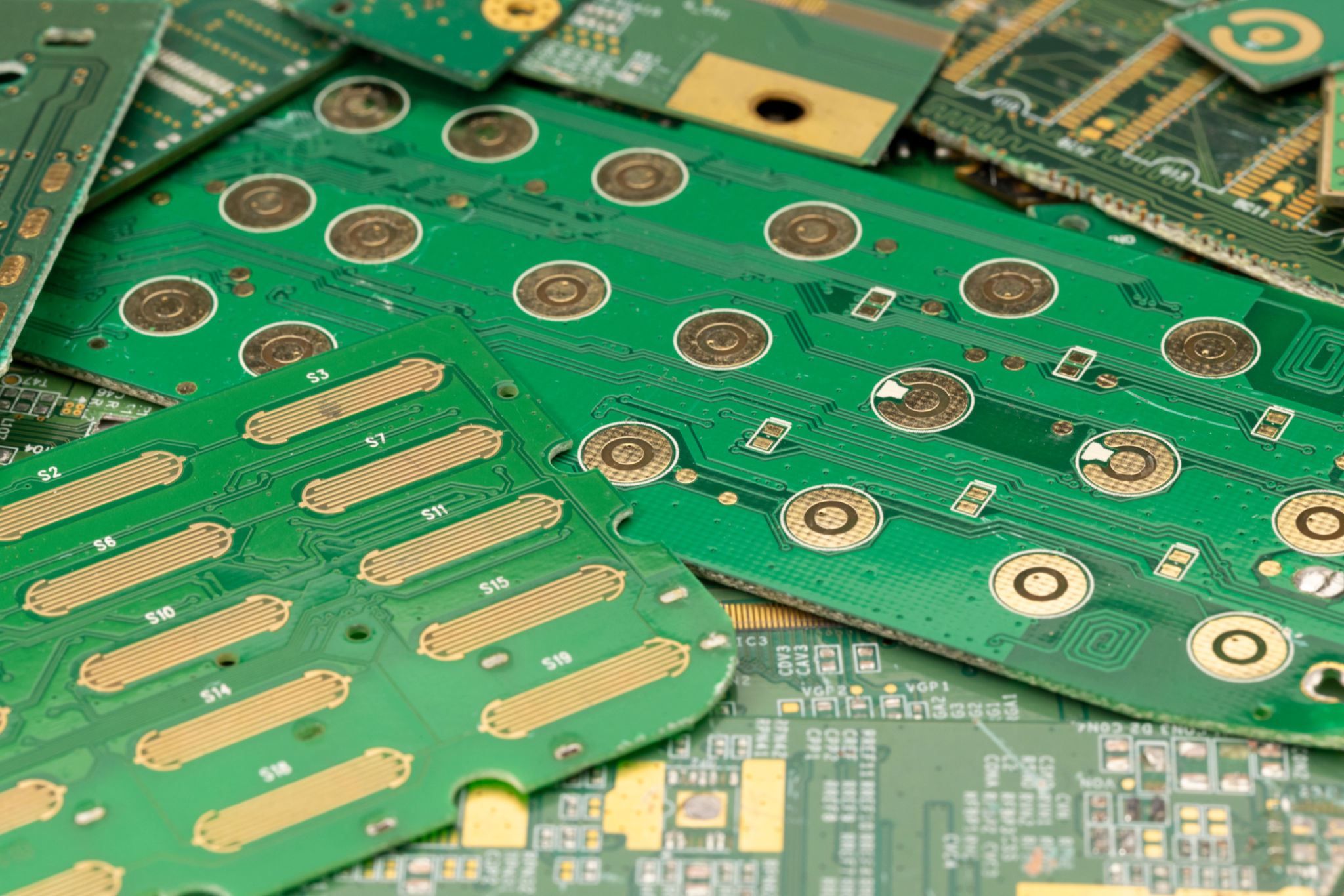

Electroplating is an essential process in many Turkish industries, including automotive, electronics, jewelry, and aerospace. In the automotive sector, for instance, electroplating is used to enhance the durability and appearance of parts like bumpers and rims. The electronics industry relies on electroplating for circuit boards and connectors to ensure optimal performance.

The jewelry industry benefits from electroplating by adding precious metal coatings to improve the aesthetic value and longevity of items. Additionally, aerospace components require high levels of precision and durability, which can be achieved through advanced electroplating techniques.

Advantages of Electroplating

Electroplating offers several advantages that make it indispensable for various industrial applications:

- Corrosion Resistance: Protects metals from environmental degradation.

- Improved Appearance: Enhances visual appeal through decorative coatings.

- Increased Durability: Provides a harder surface to withstand wear and tear.

- Electrical Conductivity: Essential for electronic components requiring efficient current flow.

Challenges in Electroplating

While electroplating provides numerous benefits, it also presents certain challenges. Managing waste and reducing environmental impact are critical concerns due to the hazardous chemicals involved. Proper disposal and recycling measures need to be implemented to minimize ecological damage.

Furthermore, maintaining consistent quality can be challenging due to variables such as temperature, current density, and bath composition. Industries must invest in precise control systems and regular monitoring to ensure consistent results.

Conclusion: Embracing Electroplating for Future Growth

Electroplating systems offer vast potential for enhancing product quality and durability across various Turkish industries. By understanding the components, applications, and challenges associated with electroplating, businesses can optimize their processes and remain competitive in a global market.

The integration of advanced technologies and sustainable practices in electroplating can further enhance efficiency and environmental responsibility. As Turkish industries continue to grow, embracing electroplating with a comprehensive understanding will be key to future success.