Step-by-Step: Implementing an Automated Kaplama Tesisi in Your Facility

Understanding the Basics of Kaplama Tesisi Automation

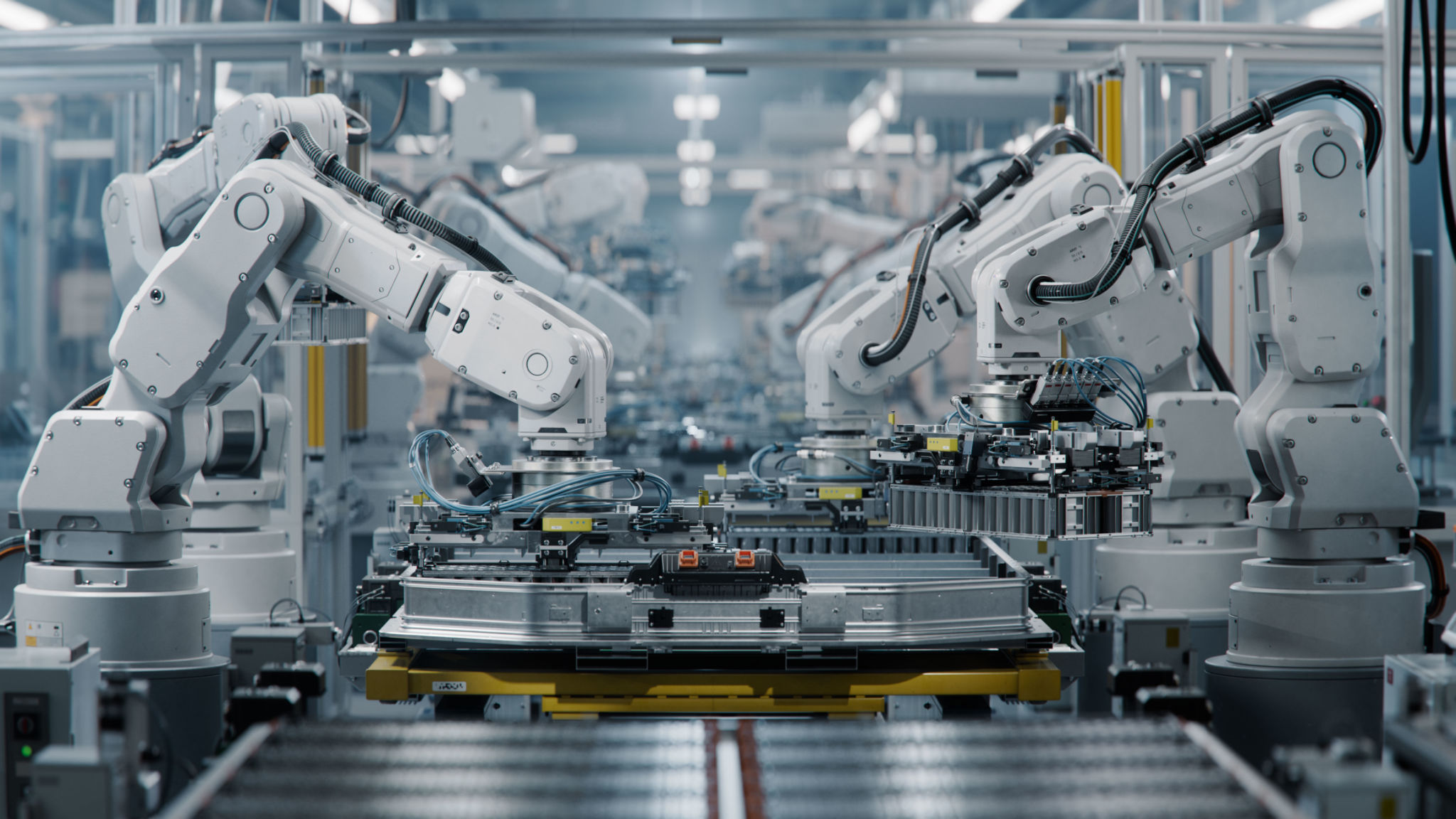

Implementing an automated Kaplama Tesisi, or coating facility, can revolutionize your manufacturing process by enhancing efficiency and consistency. Before diving into the implementation, it's crucial to understand the fundamentals of what an automated system entails. An automated Kaplama Tesisi utilizes advanced machinery and software to apply coatings to materials with minimal human intervention, reducing errors and waste.

Automation in a coating facility involves several components, such as robotic arms for application, conveyor systems for material movement, and sensors for quality control. These elements work in harmony to ensure precise and uniform coatings, which are critical in industries like automotive, aerospace, and electronics.

Planning Your Automation Strategy

Before implementing automation, it's vital to develop a comprehensive strategy. Start by identifying the specific needs of your facility. Determine which processes can benefit most from automation and assess the potential impact on production capacity and quality. Consider factors such as budget, available space, and existing infrastructure.

Engage with stakeholders, including engineers, operators, and management, to gather insights and expectations. This collaborative approach helps in setting realistic goals and timelines. Additionally, conducting a cost-benefit analysis can guide your decision-making process.

Choosing the Right Technology

Selecting the appropriate technology is a critical step in automating a Kaplama Tesisi. There are various options available, from simple robotic systems to complex integrated solutions. Consider factors like scalability, compatibility with existing systems, and ease of use when evaluating different technologies.

It's also important to choose a technology provider with a strong track record and excellent customer support. They can offer valuable guidance during the implementation phase and provide ongoing maintenance and updates.

Implementing the Automation System

Once you have chosen the right technology, it's time to implement the system. Begin with a pilot project to test the system's functionality and identify any potential issues. This allows for adjustments before a full-scale rollout.

- Install robotic arms and configure them for specific coating tasks.

- Set up conveyor systems for seamless material flow.

- Integrate sensors and cameras for real-time monitoring and quality control.

Training your workforce is a crucial aspect of implementation. Ensure that operators are well-versed in operating the new system and handling any troubleshooting that may arise. This not only enhances productivity but also minimizes downtime.

Monitoring and Optimization

After implementing the automated system, continuous monitoring is essential to ensure it operates optimally. Use data from sensors and software analytics to track performance metrics such as speed, accuracy, and efficiency.

Regular maintenance checks and updates will keep the system running smoothly. Additionally, encouraging feedback from operators can provide insights into potential improvements. By fostering a culture of continuous improvement, your facility can adapt to changing demands and maintain its competitive edge.

Reaping the Benefits

The successful implementation of an automated Kaplama Tesisi brings numerous benefits. Increased production speed and reduced errors lead to higher output and better product quality. Moreover, automation enhances safety by minimizing manual handling of hazardous materials.

In the long run, these advantages translate into significant cost savings and higher profitability. By staying ahead of technological advancements, your facility can continue to thrive in an increasingly competitive market.