Seasonal Maintenance Tips for Surface Treatment Systems

Importance of Seasonal Maintenance

Surface treatment systems are integral to many industrial processes, providing essential protection and finishing to materials. Regular maintenance ensures these systems operate efficiently and prolongs their lifespan. As seasons change, different environmental factors can affect equipment performance. Therefore, adopting a seasonal maintenance routine is crucial for optimal operation.

Spring Preparation

Spring is a time of renewal, making it the perfect opportunity to prepare your surface treatment systems for heavier usage. This season involves a thorough inspection and cleaning of all components. Dust and debris accumulated over winter can hinder efficiency, so ensure filters, nozzles, and ventilation systems are clear.

Moreover, check for any signs of wear and tear that winter might have exacerbated. Pay special attention to seals and gaskets, as temperature fluctuations can cause expansion and contraction, leading to potential leaks.

Summer Optimization

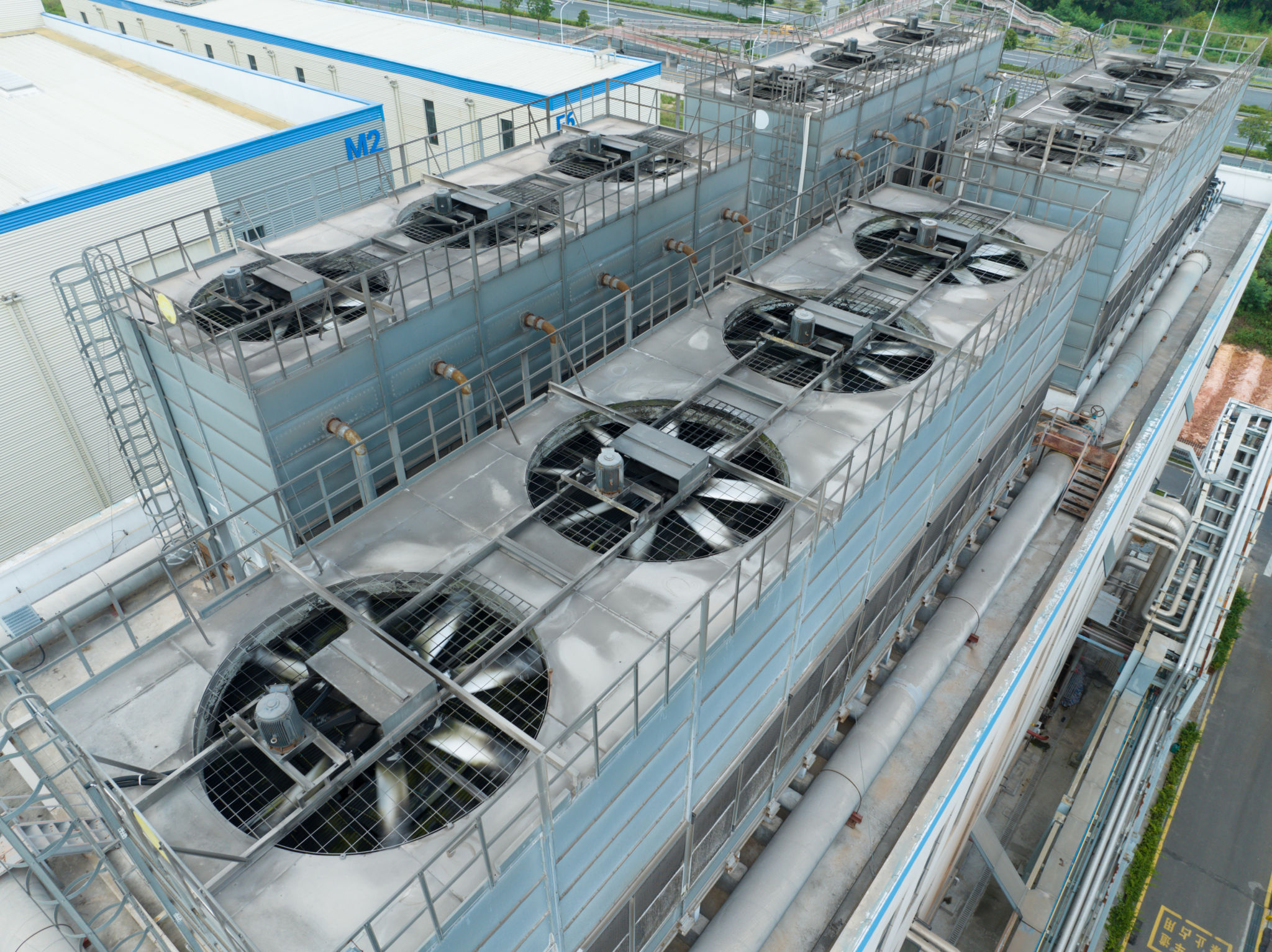

With the arrival of summer, temperatures can rise significantly, potentially impacting your equipment's cooling systems. It is vital to monitor and maintain adequate cooling to prevent overheating. Regular checks on coolant levels and ensuring proper ventilation are essential tasks during this period.

Additionally, summer is an excellent time to schedule any major repairs or upgrades, as the longer daylight hours allow for extended maintenance windows. Implementing these tasks during summer can reduce disruptions during peak operational times in other seasons.

Fall Inspection

As fall approaches, it’s time to inspect your systems for any wear incurred during the summer. Focus on corrosion prevention strategies, as humidity and temperature variations can accelerate rusting. Apply protective coatings where necessary and replace any corroded parts immediately.

Fall is also the ideal time to review operational protocols and ensure all staff are trained in the latest maintenance techniques. This ensures everyone is prepared for the operational challenges that colder months might bring.

Winter Precautions

Winter brings its own set of challenges with colder temperatures potentially affecting the viscosity of treatment fluids and the performance of machinery. It is important to adjust operational parameters to account for these changes, such as increasing fluid temperatures or utilizing antifreeze solutions.

Ensure that all heating elements are functioning correctly and that insulation is intact to maintain system performance. Regularly monitor for any signs of freezing or blockages in pipes and hoses.

Creating a Maintenance Schedule

A well-organized maintenance schedule is key to effective seasonal care. Consider creating a checklist for each season that includes all necessary tasks. This helps ensure nothing is overlooked and provides a record of maintenance activities for future reference.

- Inspect and clean components regularly.

- Check fluid levels and adjust as needed.

- Monitor for wear and replace parts timely.

- Ensure staff are well-trained in maintenance procedures.

Conclusion

Incorporating seasonal maintenance into your routine not only enhances the performance of surface treatment systems but also extends their life span. By addressing the specific challenges each season presents, you can ensure your equipment remains in top condition year-round. A proactive approach to maintenance not only saves time and money in the long run but also ensures a consistent quality of output from your surface treatment processes.