Mastering the Future: How Automation Enhances Surface Treatment Processes

The Role of Automation in Surface Treatment

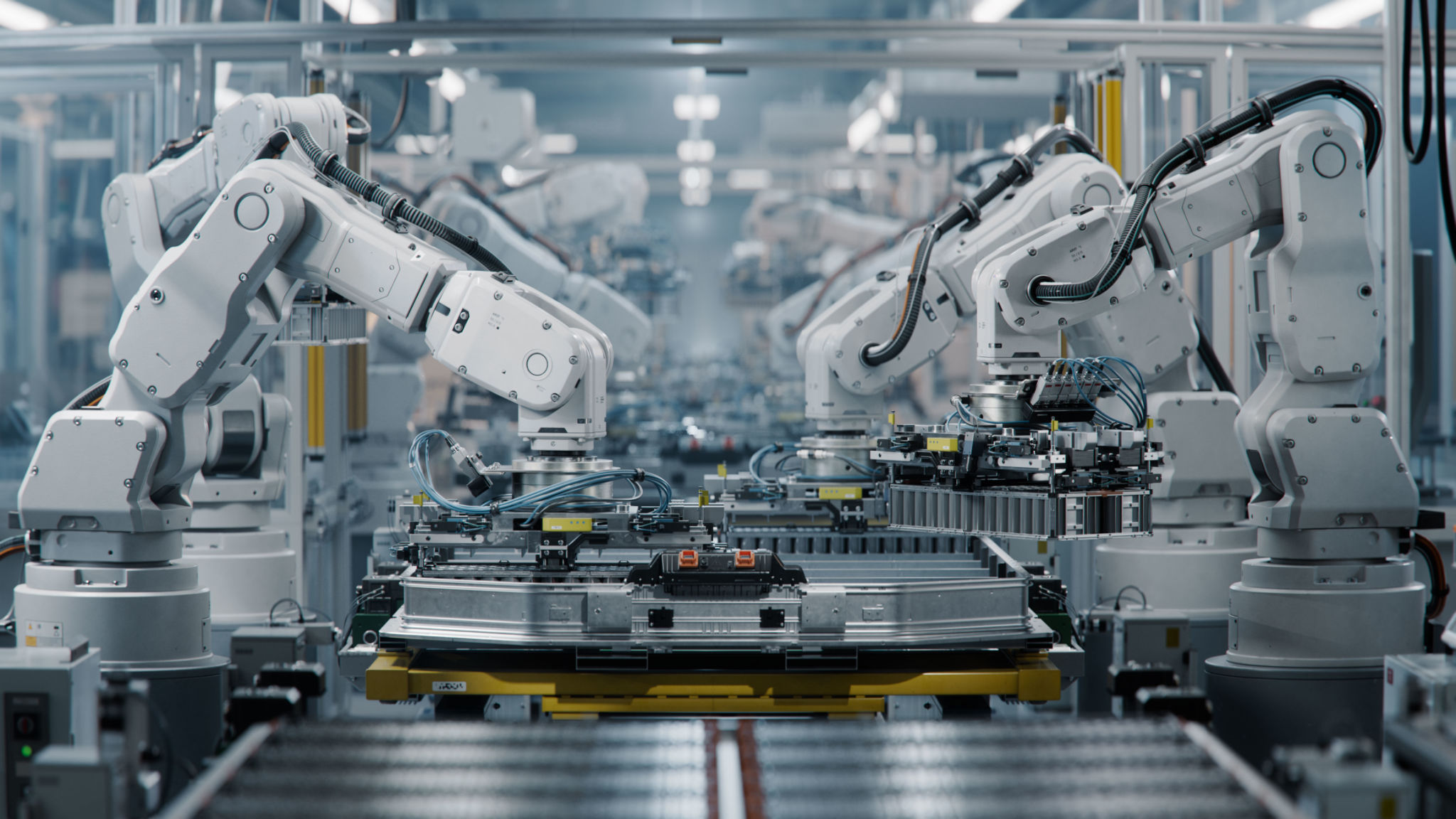

In today's fast-paced industrial landscape, automation has become a cornerstone of innovation, particularly in manufacturing processes. One area where automation is making significant strides is in surface treatment processes. By integrating automated systems, companies can achieve greater efficiency, consistency, and precision, enhancing the overall quality of their products.

Surface treatment is crucial for improving the durability, appearance, and functionality of products. Whether it's metal plating, painting, or anodizing, these processes require meticulous attention to detail. Automation helps streamline these tasks, reducing manual labor and minimizing human error.

Key Benefits of Automation in Surface Treatment

Improved Efficiency and Productivity

One of the most significant advantages of integrating automation into surface treatment is the boost in efficiency. Automated systems can work continuously without fatigue, unlike human operators. This constant operation increases productivity and allows businesses to meet high demand without compromising on quality.

Additionally, automated systems can process multiple items simultaneously, further enhancing throughput. This capability significantly reduces production time and helps companies maintain competitive lead times in the market.

Enhanced Precision and Consistency

Automation ensures a remarkable level of precision and consistency in surface treatment processes. Manual operations are prone to variations due to human factors, but automated systems follow programmed instructions meticulously. This precision leads to consistent product quality and finish, which is vital for industries where aesthetics and functionality are paramount.

By maintaining strict control over variables like temperature, pressure, and application rates, automated systems ensure that each product receives the exact same treatment. This uniformity is essential in industries such as automotive and aerospace, where even the slightest deviation can impact performance.

Sustainability and Cost Reduction

Resource Efficiency

Automation contributes to sustainability by optimizing the use of resources. Automated systems are designed to use materials efficiently, reducing waste and minimizing environmental impact. This eco-friendly approach not only benefits the planet but also results in cost savings for businesses.

Furthermore, by reducing energy consumption through more efficient processes, companies can significantly cut operational costs, making automation a financially viable solution for surface treatment.

Reduced Labor Costs

While the initial investment in automation technology can be substantial, the long-term savings are considerable. Automated systems reduce the need for extensive manual labor, lowering labor costs while reallocating human resources to more strategic roles within the organization. This shift not only enhances operational efficiency but also empowers employees to focus on innovation and problem-solving.

The Future of Surface Treatment with Automation

As technology continues to evolve, so too will the capabilities of automated systems in surface treatment. The integration of artificial intelligence and machine learning into these processes promises even greater advancements. AI can analyze data from automated systems to continuously optimize operations, predict maintenance needs, and further enhance efficiency.

Ultimately, mastering the future of surface treatment through automation will involve a combination of cutting-edge technology and strategic implementation. Companies that embrace these innovations will not only improve their production processes but also gain a competitive edge in an ever-evolving market.