How to Optimize Surface Treatment Processes with Advanced Automation in Bursa

Understanding Surface Treatment Processes

Surface treatment processes are essential in various industries, especially in manufacturing, to enhance the durability, appearance, and performance of materials. These processes include coating, plating, cleaning, and painting, each with its specific requirements and challenges. In Bursa, a city known for its industrial prowess, optimizing these processes can lead to significant improvements in production efficiency and product quality.

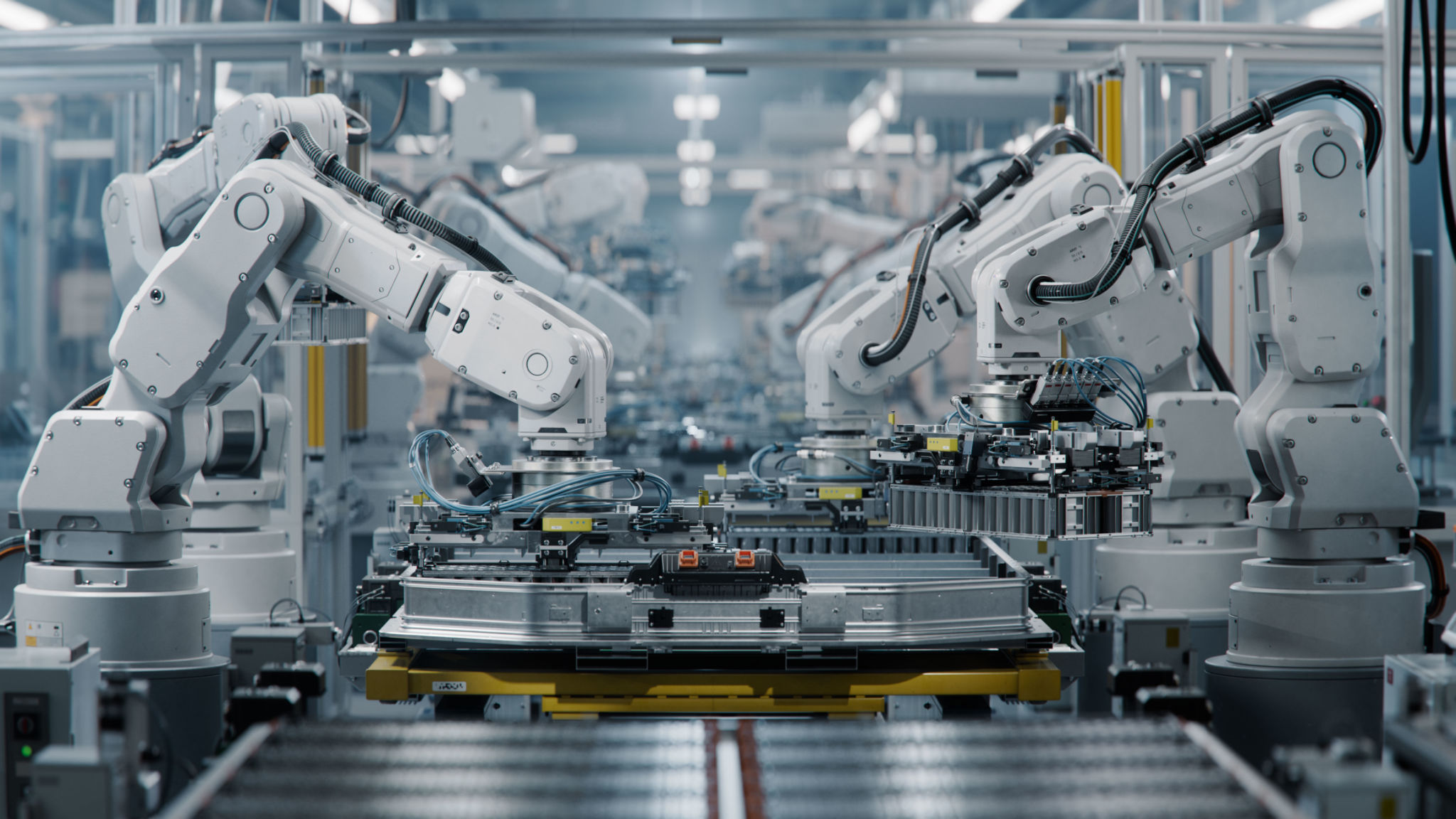

The Role of Advanced Automation

Advanced automation plays a critical role in optimizing surface treatment processes. By integrating automated systems, businesses can achieve greater precision and consistency in their operations. Automation reduces human error, increases process speed, and ensures that each product meets the required standards. In Bursa's competitive market, leveraging these technologies can provide a significant edge.

Benefits of Automation in Surface Treatment

Implementing automation in surface treatment processes offers several benefits. Firstly, it enhances efficiency by streamlining operations and minimizing downtime. Secondly, it improves consistency, ensuring that every product is treated to the same high standard. Finally, automation contributes to cost savings by reducing waste and optimizing resource usage.

Key Technologies in Automation

The automation of surface treatment processes involves various cutting-edge technologies. Some of the most effective include:

- Robotic Arms: These are used for precision handling and application of surface treatments.

- Automated Conveyor Systems: These systems ensure a seamless flow of materials through different stages of treatment.

- Advanced Sensors: Sensors monitor conditions in real-time, allowing for immediate adjustments to optimize the process.

Implementing Automation in Bursa

Bursa's industrial sector is well-positioned to implement advanced automation due to its strong infrastructure and skilled workforce. Companies can start by assessing their current processes to identify areas that would benefit most from automation. Collaborating with technology providers can help businesses select the right tools and technologies tailored to their specific needs.

Challenges and Solutions

While automation offers many advantages, it also presents challenges such as initial investment costs and the need for workforce training. However, these challenges can be mitigated through strategic planning and phased implementation. Government incentives and support programs available in Bursa can also ease the transition for local businesses.

The Future of Surface Treatment in Bursa

As Bursa continues to grow as a hub for industrial innovation, the future of surface treatment looks promising. With ongoing advancements in automation technology, businesses can expect even more efficient, sustainable, and cost-effective processes. Staying ahead of these trends will be crucial for companies aiming to maintain a competitive edge in the global market.

Conclusion

Optimizing surface treatment processes with advanced automation is not just a trend but a necessity in Bursa's industrial landscape. By embracing these technologies, businesses can enhance their operational efficiency, improve product quality, and achieve substantial cost savings. As the industry evolves, those who invest in automation today will be best positioned for success tomorrow.