Exploring the Best Automation Systems for Surface Treatment

Introduction to Surface Treatment Automation

Surface treatment plays a crucial role in enhancing the durability and aesthetic appeal of products across various industries. As technology advances, automation systems have become integral to streamlining these processes, improving efficiency, and ensuring consistent quality. In this post, we'll explore some of the best automation systems for surface treatment and how they can benefit your operations.

Automation in surface treatment involves the use of machines and software to perform tasks traditionally done by human operators. This includes processes such as cleaning, coating, and painting. By automating these tasks, companies can achieve faster production rates, reduce waste, and improve product quality.

Types of Automation Systems for Surface Treatment

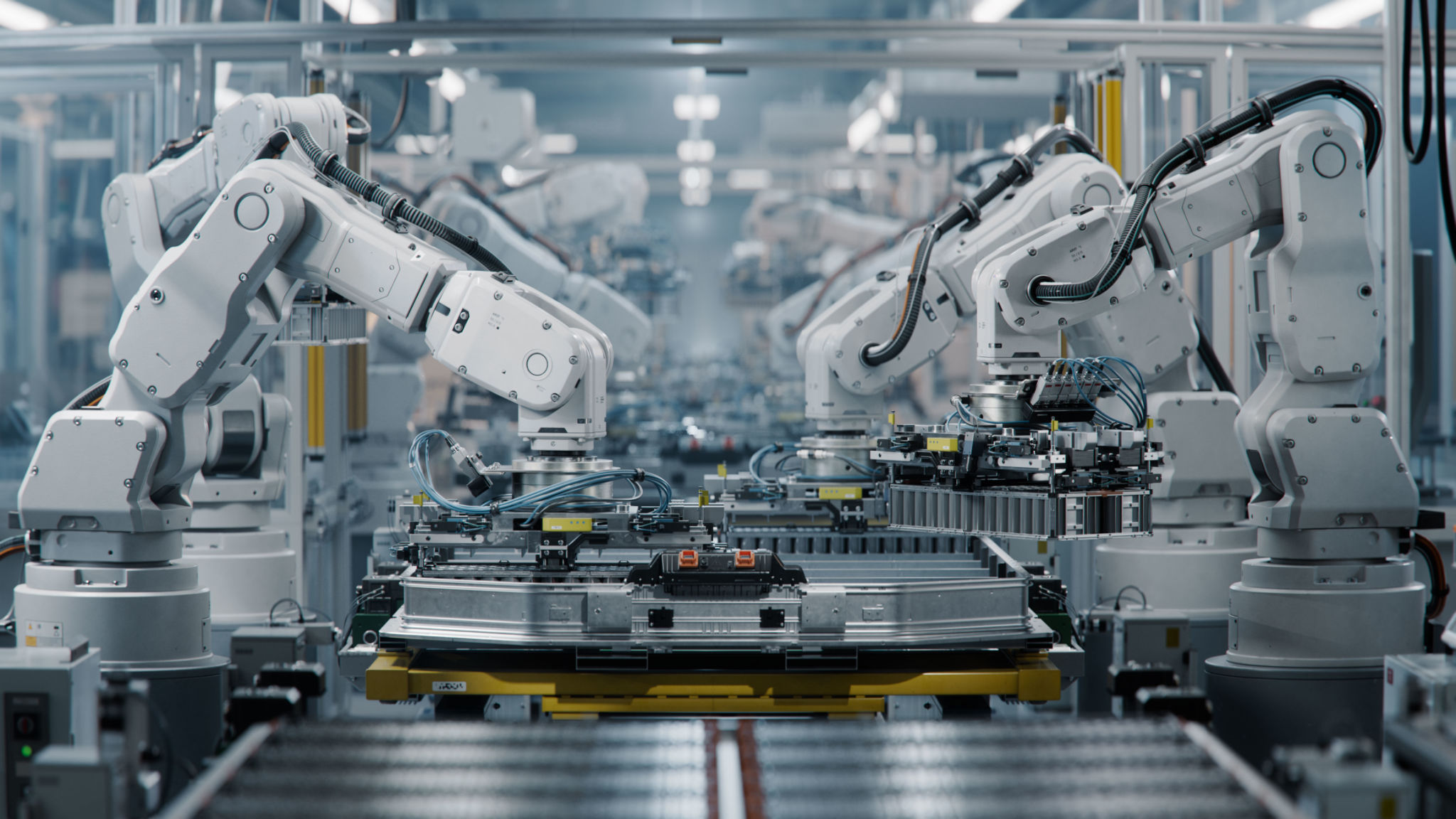

Robotic Arm Systems

Robotic arms are widely used in surface treatment for their precision and adaptability. These systems can be programmed to perform a variety of tasks, from applying coatings to polishing surfaces. The flexibility of robotic arms allows them to handle complex shapes and sizes, ensuring every part is treated uniformly.

Automated Conveyor Systems

Conveyor systems are essential for transporting parts through different stages of surface treatment. Automated conveyors ensure seamless movement between cleaning, coating, and curing stations. These systems can be customized to fit specific production lines, optimizing the flow of materials and reducing manual handling.

Benefits of Automating Surface Treatment

The primary advantage of automation in surface treatment is increased efficiency. Automated systems work continuously without fatigue, allowing for higher throughput and reduced cycle times. This results in faster production and quicker turnaround times for clients.

Another significant benefit is consistency. Automated systems apply treatments uniformly across all surfaces, minimizing defects and ensuring high-quality finishes. This level of consistency is difficult to achieve with manual processes, where variability can lead to uneven coatings or missed spots.

Choosing the Right Automation System

Selecting the right automation system for your surface treatment needs depends on several factors, including the size and complexity of your products, production volume, and budget. It's essential to assess your specific requirements and consult with experts to determine the best solution for your operations.

When choosing an automation system, consider the level of customization required. Some systems offer modular designs that can be tailored to fit unique production lines, while others provide standard configurations suitable for a wide range of applications.

The Future of Surface Treatment Automation

The future of surface treatment automation is promising, with advancements in artificial intelligence and machine learning paving the way for even more sophisticated systems. These technologies will enable predictive maintenance, further reducing downtime and improving overall efficiency.

As industries continue to embrace automation, we can expect to see innovations that enhance not only productivity but also sustainability. Automated systems are likely to incorporate eco-friendly practices, such as reducing energy consumption and minimizing waste.

Conclusion

Automation systems have revolutionized surface treatment by improving efficiency, consistency, and quality. Whether you're considering robotic arms or automated conveyor systems, investing in automation can significantly enhance your operations. By staying informed about the latest trends and technologies, businesses can remain competitive in an ever-evolving market.