Comprehensive Guide to Surface Treatment Automation in Bursa

In recent years, Bursa has become a hub for industrial innovation, particularly in the field of surface treatment automation. With an increasing demand for high-quality finishes and efficient production processes, many companies in Bursa are turning to automation to stay competitive. Surface treatment automation not only improves efficiency but also enhances the quality and consistency of the final product.

Understanding Surface Treatment Automation

Surface treatment automation involves the use of automated systems to apply coatings, paints, or other finishes to surfaces. This process can include cleaning, priming, painting, and finishing. By automating these processes, manufacturers in Bursa can achieve higher precision and repeatability, reducing the risk of human error.

Automation in surface treatment also allows for better control over environmental factors such as temperature and humidity, which can significantly impact the quality of the finish. Advanced systems can adjust these factors in real time, ensuring optimal conditions for each specific job.

Benefits of Automation

There are several key benefits to implementing automation in surface treatment:

- Increased Efficiency: Automated systems can operate continuously, reducing downtime and increasing throughput.

- Consistent Quality: Automation ensures uniform application of coatings, enhancing product quality and reducing defects.

- Cost Savings: By reducing waste and improving efficiency, companies can lower operational costs.

- Safety Improvements: Automation reduces the need for human workers to be in potentially hazardous environments.

Key Technologies in Surface Treatment Automation

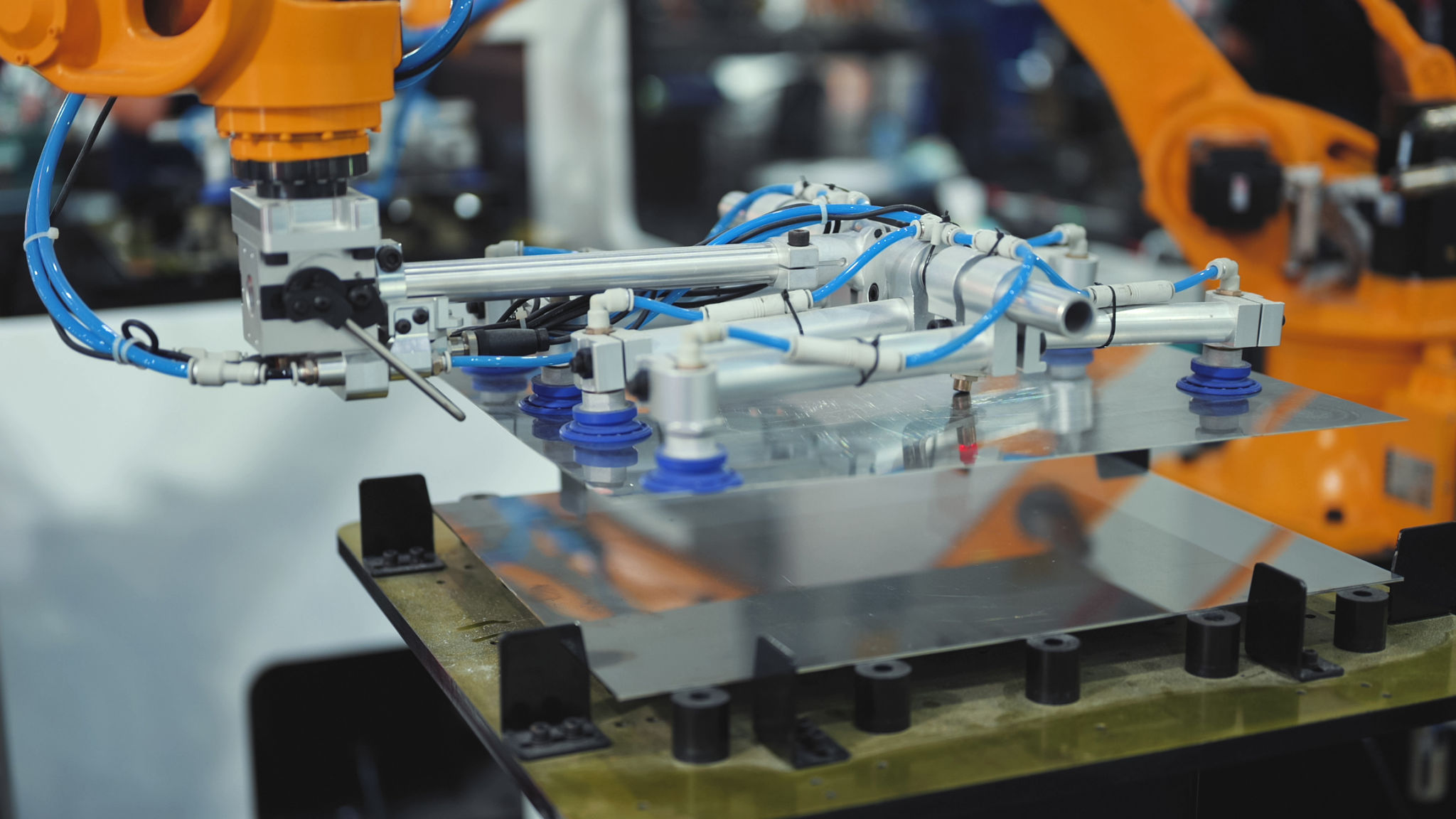

Several technologies are driving the evolution of surface treatment automation in Bursa. Robotics is at the forefront, with robotic arms performing tasks with high precision and speed. These robots can be programmed to handle various tasks, from cleaning to painting, with minimal human intervention.

Additionally, Artificial Intelligence (AI) and Machine Learning (ML) are increasingly being integrated into surface treatment systems. These technologies allow for predictive maintenance, where systems can anticipate and address potential issues before they lead to downtime. AI-driven analytics also provide valuable insights into process optimization.

Challenges and Considerations

While the benefits of automation are clear, there are challenges that companies in Bursa must navigate. Initial setup costs can be high, and integrating new technologies with existing systems may require significant effort. Companies must also invest in training employees to work alongside automated systems effectively.

Another consideration is the need for customization. Each industry and company may have unique requirements for surface treatment, necessitating tailored solutions that can adapt to specific needs and conditions.

The Future of Surface Treatment Automation in Bursa

Looking ahead, the future of surface treatment automation in Bursa is promising. As technology continues to advance, we can expect even more sophisticated systems that offer greater efficiency and precision. The integration of IoT (Internet of Things) devices will further enhance connectivity and data collection, enabling smarter, more adaptive processes.

As Bursa continues to embrace these innovations, it will solidify its position as a leader in industrial automation, driving growth and competitiveness in the region's manufacturing sector. Investing in automation today will pave the way for a more sustainable and efficient future.