Case Study: Successful Electroplating Automation in Bursa

Introduction to Electroplating Automation in Bursa

Electroplating has long been an integral process in manufacturing, providing a durable and aesthetically pleasing finish to various products. The city of Bursa, known for its rich industrial heritage, has recently witnessed a transformative shift with the successful automation of electroplating. This case study explores the implementation, challenges, and outcomes of this significant advancement.

The Need for Automation

Traditional electroplating methods, while effective, often face challenges such as inconsistent quality, labor-intensive processes, and environmental concerns. In Bursa, the demand for high-quality finishes in automotive and electronics sectors necessitated a more efficient approach. Automation emerged as a solution to streamline operations, reduce human error, and enhance overall productivity.

Implementation Process

The transition from manual to automated electroplating involved several stages. Initially, a comprehensive analysis was conducted to assess the existing processes and identify areas for improvement. Key steps included:

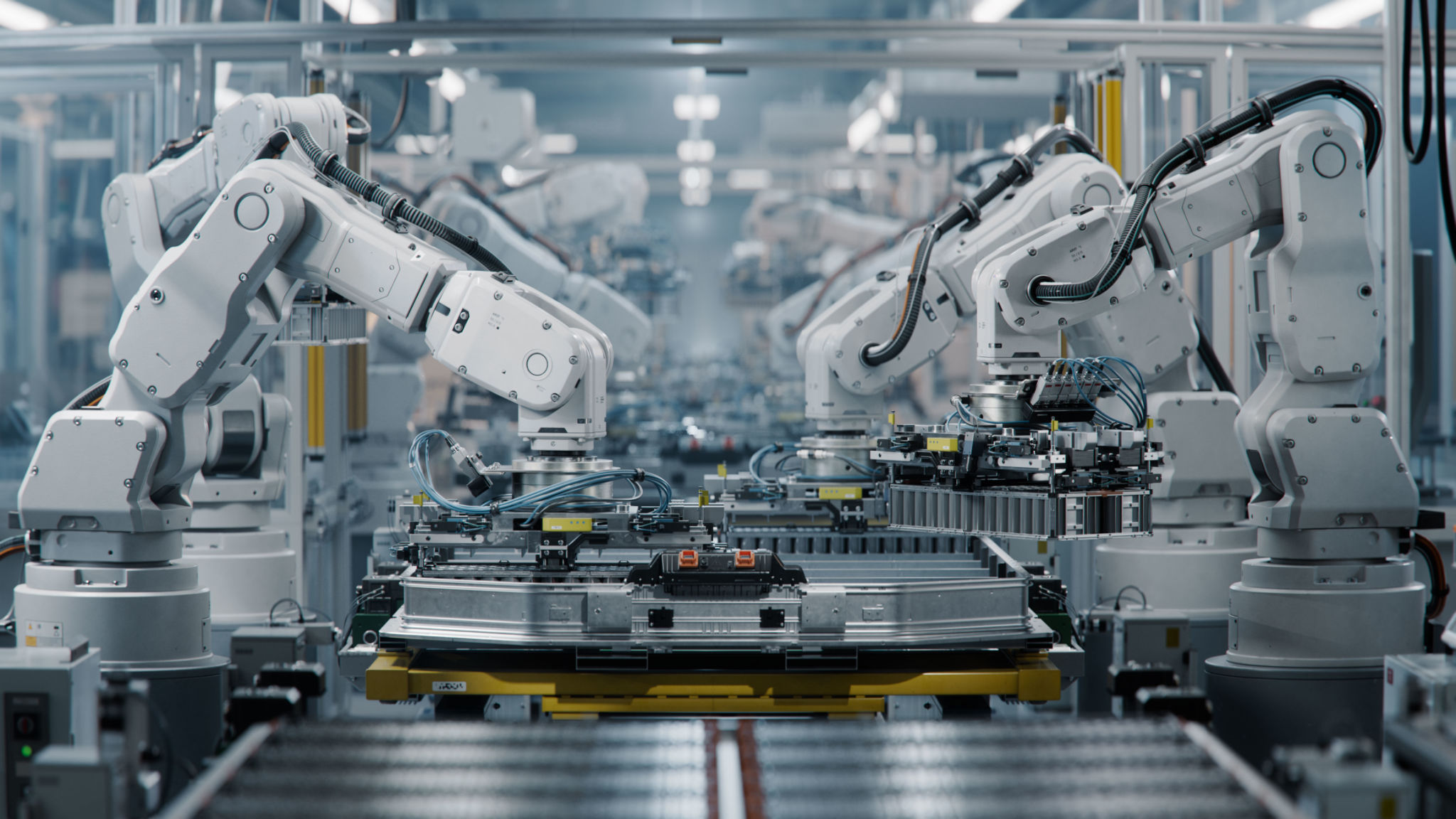

- Integrating advanced robotics to handle repetitive tasks.

- Implementing IoT devices for real-time monitoring.

- Utilizing data analytics to optimize plating conditions.

This systematic approach ensured a smooth transition with minimal disruption to ongoing operations.

Overcoming Challenges

Despite its potential benefits, the automation process was not without challenges. One significant hurdle was the initial cost of investment in new technology and training. Additionally, there was a learning curve associated with adopting new systems. However, strategic planning and support from technology partners facilitated overcoming these barriers.

Benefits of Automation

The benefits realized from automating the electroplating process in Bursa were substantial. Key advantages included:

- Increased Efficiency: Automation reduced processing time and increased throughput.

- Enhanced Quality: Consistent application of coatings improved product quality.

- Environmental Benefits: Optimized resource usage minimized waste and emissions.

Impact on the Local Industry

The successful implementation of electroplating automation has set a precedent in Bursa’s manufacturing sector. It not only improved operational efficiency but also positioned local businesses as competitive players in the global market. This technological advancement has attracted further investments and interest from international partners.

Future Prospects

Looking ahead, the future of electroplating in Bursa is promising. There are plans to further integrate artificial intelligence to predict maintenance needs and enhance decision-making processes. As technology evolves, there is potential for even greater innovations that can redefine standards within the industry.

Conclusion

The transition to automated electroplating in Bursa serves as an inspiring example of innovation driving industrial growth. By embracing modern technology, local manufacturers have not only improved their processes but also secured a competitive edge in a rapidly evolving market. This case study underscores the importance of adaptability and forward-thinking in achieving sustainable success.