A Comprehensive Guide to Implementing Automation in Electroplating

Introduction to Automation in Electroplating

In the rapidly evolving manufacturing landscape, automation has become a cornerstone of efficiency and precision. Electroplating, a process used to coat objects with a thin layer of metal, can greatly benefit from automation, reducing human error and enhancing production speed. This guide explores how to implement automation in electroplating effectively.

Understanding the Basics of Electroplating

Electroplating involves the deposition of a metal coating onto a surface using an electric current. It is widely used across industries for improving corrosion resistance, enhancing appearance, and increasing thickness. The process requires precise control over various parameters such as temperature, voltage, and plating time.

The traditional methods of electroplating are labor-intensive and prone to inconsistencies. Automation can not only streamline these operations but also ensure uniformity and high-quality output.

Benefits of Automating Electroplating

Automating the electroplating process comes with several advantages. Firstly, it significantly reduces manual labor, allowing workers to focus on more strategic tasks. Secondly, it improves safety by minimizing the exposure of workers to potentially hazardous chemicals. Thirdly, automation enhances consistency and precision, leading to superior product quality.

Key Components of an Automated Electroplating System

To implement automation in electroplating, certain components are essential:

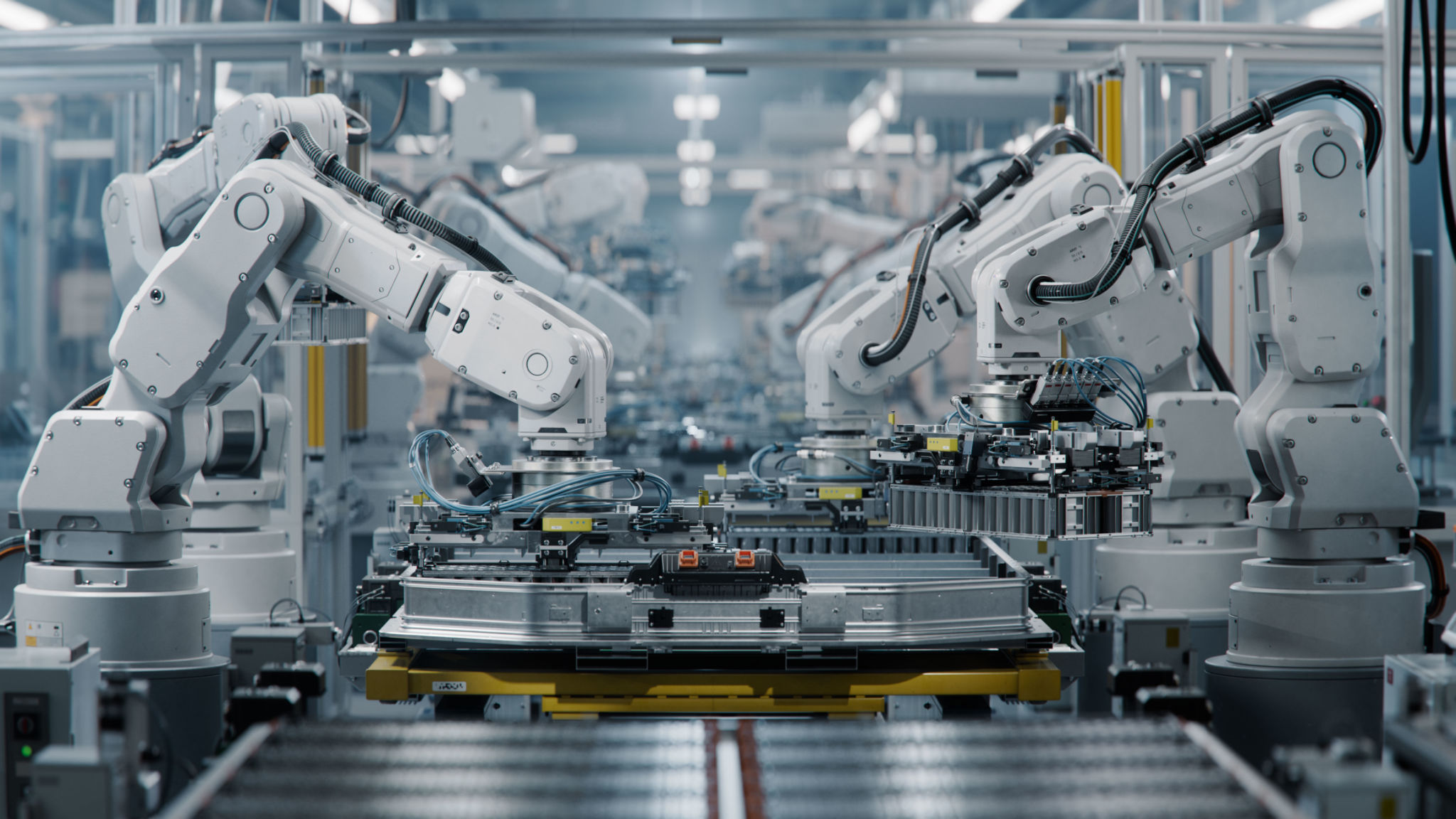

- Robotic Arms: These are used for handling materials and ensuring precise placement in plating baths.

- Sensors: They monitor critical parameters like temperature and pH levels.

- Control Systems: Software that orchestrates the entire process, adjusting variables in real-time.

Steps to Implement Automation

Implementing automation in electroplating involves several steps:

- Assessment: Evaluate current processes to identify areas where automation can be integrated.

- Design: Develop a tailored automation plan that fits the specific needs of your operations.

- Installation: Integrate robotics, sensors, and control systems into your existing setup.

- Testing: Conduct thorough testing to ensure everything operates smoothly.

- Training: Train staff on the new systems for effective management and troubleshooting.

Overcoming Challenges in Automation

While automation offers numerous benefits, it also comes with challenges. Initial setup costs can be high, and there is a learning curve involved for staff. However, these challenges are offset by long-term gains in efficiency and productivity.

The Future of Automated Electroplating

The future of electroplating lies in further advancements in automation technology. As AI and machine learning continue to evolve, they will enable even greater levels of optimization and control within the electroplating process. Embracing these technologies now will ensure businesses remain competitive in an ever-changing market.

By following this comprehensive guide, manufacturers can successfully implement automation in their electroplating processes, paving the way for enhanced productivity and quality in their operations.